Enhancing Item Development with Advanced Plastic Injection Molding Solutions

Enhancing Item Development with Advanced Plastic Injection Molding Solutions

Blog Article

Secret Benefits of Making Use Of Plastic Shot Molding in Production

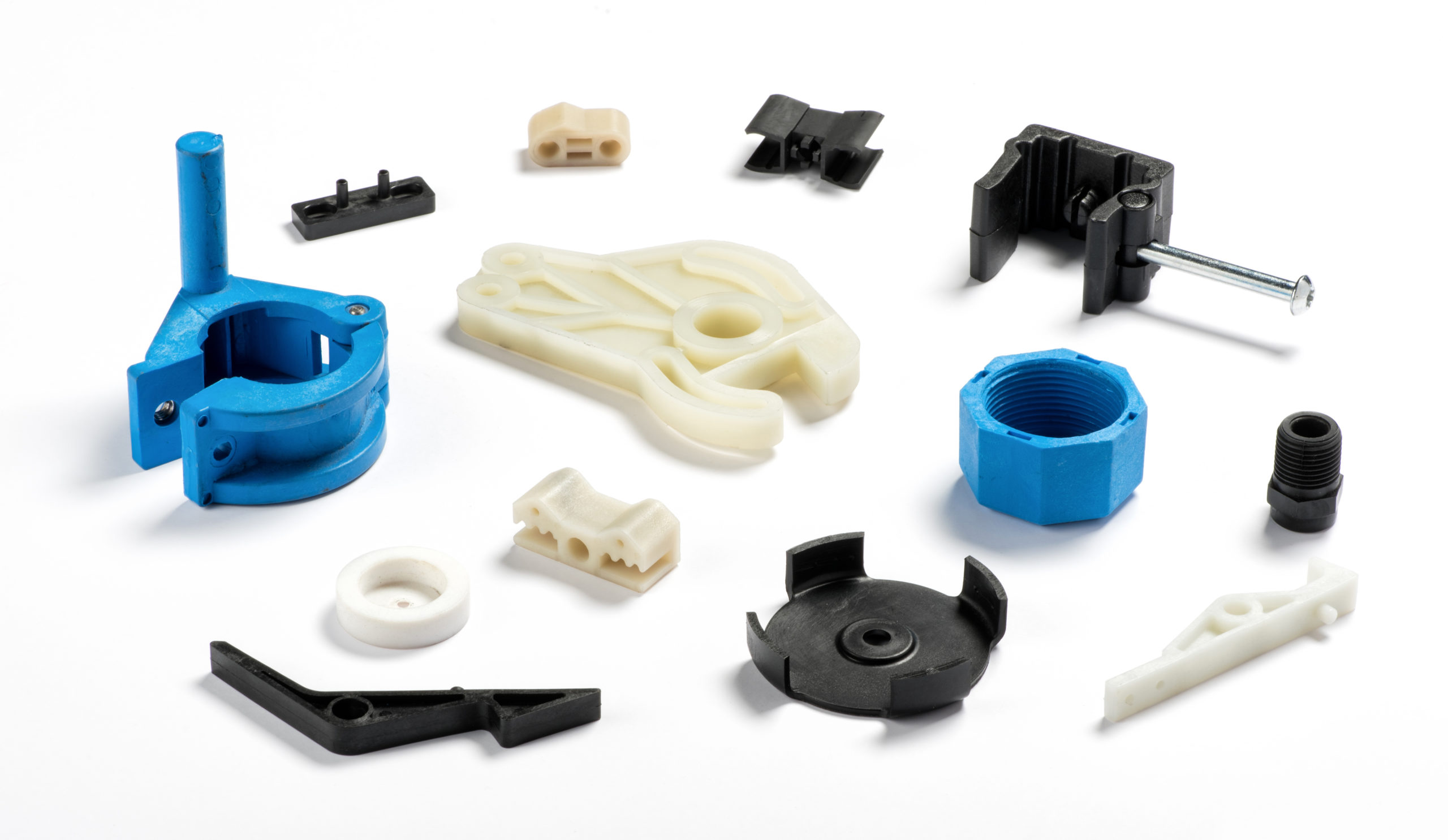

Plastic shot molding has actually emerged as a crucial technique in the manufacturing market, supplying a variety of advantages that substantially enhance manufacturing procedures. Remarkable advantages consist of exceptional manufacturing performance, the capability for detailed designs, and a beneficial cost structure that allures to organizations of all dimensions.

High Production Efficiency

One of one of the most considerable advantages of plastic injection molding is its high manufacturing effectiveness, which can result in the rapid manufacturing of hundreds of similar parts within a short duration. This effectiveness is largely credited to the automated nature of the injection molding process. As soon as the preliminary setup and mold and mildew development are finished, the manufacturing of parts can be scaled up dramatically without a corresponding boost in labor prices or time.

The procedure normally entails heating plastic pellets till they thaw, infusing the molten material right into an exactly made mold, and permitting it to cool down and solidify - Plastic Injection Molding. This cycle can be finished in simple secs to minutes, depending upon the complexity and size of the part being created. As an outcome, manufacturers can accomplish high output prices, making plastic injection molding an ideal selection for automation

Furthermore, the capacity to produce large amounts continually makes certain lower device costs, making it a cost-effective service for businesses. This production performance not just meets market needs swiftly but additionally improves the overall competitiveness of makers in numerous industries. Plastic injection molding continues to be a favored method for high-volume manufacturing applications.

Layout Flexibility

The capacities of plastic injection molding prolong beyond high manufacturing effectiveness to incorporate considerable layout versatility. This manufacturing procedure permits engineers and developers to produce complicated and detailed shapes that may be tough or impossible to accomplish with other approaches (Plastic Injection Molding). The capability to quickly adjust and modify mold and mildew styles suggests that makers can swiftly react to transforming market demands and introduce brand-new item designs without substantial retooling

Moreover, plastic shot molding supports a vast range of materials, consisting of different thermoplastics and thermosetting polymers. This selection makes it possible for the manufacturing of elements with special homes, such as boosted strength, light-weight features, or particular thermal and electric characteristics. Additionally, the procedure permits the integration of multiple features into a single part, decreasing the need for assembly and decreasing possible points of failing.

The precision of shot molding also ensures that components are produced with tight tolerances, enhancing fit and function. The adaptability to create tiny to big sets effectively even more emphasizes its versatility, making it a perfect choice for both prototyping and large-scale production. In general, layout flexibility is a keystone advantage of plastic shot molding, driving development in various markets.

Cost-Effectiveness

Cost-effectiveness stands apart as a substantial benefit of plastic shot molding in production. This process permits for the automation of high-grade plastic components at a relatively low cost per device, especially when contrasted to various other making methods. The performance of shot molding hinges on its ability to generate complicated forms with marginal waste, maximizing product use and decreasing general expenditures.

In addition, the rate of production is a crucial aspect in cost-effectiveness. When the preliminary mold and mildew is created, the time required to produce each succeeding part is substantially minimized, bring about raised result and faster turn-around times. This quick manufacturing ability not just meets high-volume demands but also minimizes labor prices, as automated systems can take care of much of the procedure.

Furthermore, the resilience and longevity of injection-molded products add to their cost-effectiveness gradually. These elements typically call for much less upkeep and replacement, resulting in reduced lifecycle expenses for end-users and makers alike. In summary, the cost-effectiveness of plastic shot molding makes it an attractive alternative for businesses looking for to boost their production performance while keeping product quality.

Material Convenience

Product convenience is a trademark of plastic shot molding, allowing suppliers to select from a wide range of polymers that meet particular performance requirements. This versatility permits for the production of elements tailored to numerous applications, varying from automobile components to consumer items.

Frequently utilized products include acrylonitrile butadiene styrene (ABDOMINAL MUSCLE), polycarbonate (COMPUTER), and polypropylene (PP), each offering distinct residential properties such as impact resistance, warmth tolerance, and chemical security. Manufacturers can select materials based upon characteristics like toughness, weight, and thermal security, guaranteeing the end item satisfies visit this site visual and functional requirements.

Furthermore, the capability to incorporate different polymers with co-injection techniques additional improves product versatility. This permits the production of multi-layered components with distinctive characteristics, such as soft-touch surfaces integrated with rigid structural components.

Additionally, developments in naturally degradable and recycled materials are broadening the alternatives available, aligning with sustainability goals in production. In general, the varied product options in plastic injection molding equip suppliers to introduce and optimize their products, promoting the development of highly specialized and competitively beneficial services.

Improved Item Resilience

Enhanced product resilience is among the substantial benefits supplied by plastic shot molding, as the production procedure permits for precise control over product residential or commercial properties and component design. This accuracy makes sure that the final products exhibit boosted mechanical toughness and durability, which are Check This Out vital consider a variety of applications, from durable goods to commercial components.

Additionally, the intricate geometries attainable with injection molding allow the production of components that can endure anxiety and strain much better than typical manufacturing techniques. The uniform useful link wall surface thickness and reduced material waste likewise add to the overall honesty of the product, decreasing the possibilities of failure during its lifecycle.

Verdict

Finally, plastic shot molding offers considerable advantages in manufacturing, including high manufacturing performance, layout adaptability, and cost-effectiveness. The approach's capacity to quickly generate large amounts of similar components while lessening labor and material waste is paramount. Furthermore, the flexibility in material option adds to enhanced item toughness and lower lifecycle prices. These factors jointly establish plastic shot molding as an optimum option for mass manufacturing applications, resolving the vibrant requirements of modern manufacturing settings.

Plastic shot molding has actually emerged as an essential strategy in the manufacturing market, using a range of benefits that substantially enhance production procedures.One of the most substantial advantages of plastic injection molding is its high manufacturing efficiency, which can result in the fast production of thousands of the same components within a brief duration. Plastic Injection Molding.The capabilities of plastic injection molding expand beyond high production performance to encompass considerable style versatility.In conclusion, plastic injection molding offers significant advantages in production, consisting of high manufacturing performance, style versatility, and cost-effectiveness. These aspects jointly establish plastic shot molding as an optimal remedy for mass manufacturing applications, resolving the vibrant demands of modern-day production settings

Report this page